We've recently been investigating the benefits of different steel sections for our frame parts. Rectangular and square box section are easy to come by and have flat faces which can simplify assembly. The question is - would they be any more or less rigid?

To answer this we modelled some comparative parts on a CAD system, whilst not a definitive answer it did produce some results of interest.

Stiffness or Rigidity

For some sections the best orientation to maximise stiffness is obvious just from looking at a shape. In the example below the part can be expected to be stiffer in scenario A than in scenario B.

It is possible to visualise that the same force applied to the same material but in different orientations, will produce more or less deflection.

In this case the difference was clear, but we can use the maths behind this difference and apply it to more complex shapes. The property calculated to define this stiffness is the "Moment of Inertia" also known as the "Second Moment of Area". This mathematical value explains why the flat piece of material is more flexible in one direction than the other.

The samples.

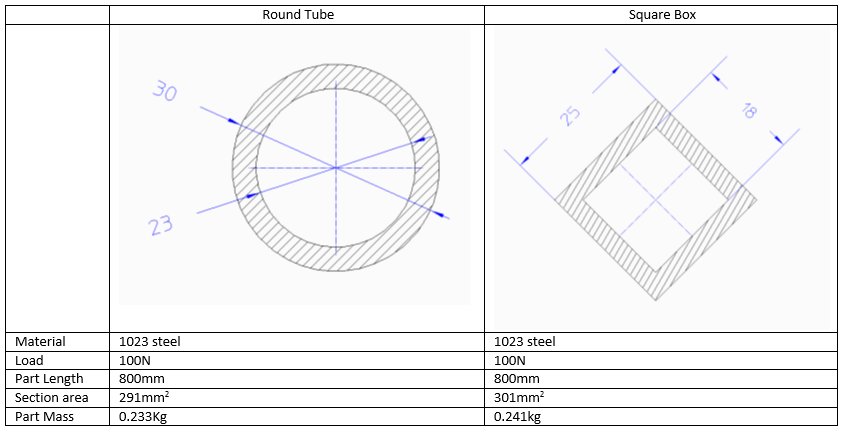

In this simple deflection modelling exercise a round tube and a square box section were created. Both were made of standard 1023 steel, had a wall thickness of 3.5mm and the test pieces were to be 800mm long.

The box section had an outside dimension of 25mm and an inside dimension of 18mm.

To make a fair comparison the round tube also had a wall thickness of 3.5mm and the overall diameter was drawn to give the same section area as the box section.

To maximise the box section stiffness in the direction of the load, it was modelled rotated at 45° to the normal axis. The table below details the parts.

Results.

The moment of inertia of the round tube was calculated to be 26024mm^4

The moment of inertia of the box section under a vertical load was 23804mm^4

This would suggest the round tube as more stiff as it had a higher second moment of area.

The simulation provided the following output.

Round tube deflection 3.199mm

Square box deflection 3.499mm

Conclusion

Although the round tube was marginally stiffer that the box section there was very little to differentiate the two. However one possible upside of the round tube would be that the stiffness would be the same in every orientation, whereas you could expect the square tube to be less stiff with a load applied perpendicular to a face. In fact a quick recalculation of the deflection of the square tube with the force perpendicular to a face, showed and increase in deflection of 42% which was equal to 7mm.

When we design our bikes we always consider simulation data like this to look out for any unexpected weaknesses. Of course nothing can replace a road test on a prototype bike, but being analytical doesn't hurt (especially when the computer's doing the hard work for you).