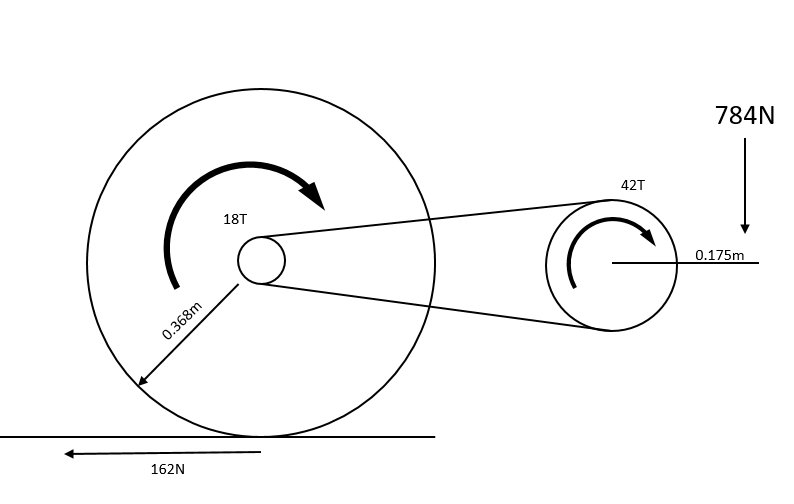

Following our recent look into electric motor torque we thought it might be useful to put some numbers into the situation so we can better understand the significance or otherwise of these torque numbers and to also compare this torque to the rider's input and other comparable numbers.For a worked example let's take an 80Kg rider using 175mm cranks, on a bike with 26" wheels; and let's fit a chain ring of 42 teeth and a freewheel of 18 teeth.First of all we need to tidy up the units80kg x Gravity = 785N175mm cranks = 0.175m26" wheels = 29" with tyres which is 736mm diameter or 0.368m radiusThe drive train ratio is 42 / 18 = 2.3When the rider stands on the pedal the torque at the bottom bracket is mass x radius which is 785N x 0.175m = 137Nm.It is interesting that most motorised vehicles use a reduction gear but in the case of a bicycle the opposite is actually true. The crank output is geared up to give more speed and less torque from the rider's legs. As a result the torque is lowered through the transmission gearing by a ratio of 2.3. This reduces the torque to 60Nm at the rear hub.The actual force then acting at the road to move the bike forward is this torque divided by the wheel radius = 60Nm / 0.368 = 162N of force.These numbers are shown in the diagram below. One of the clever things about a bicycle is that the heavier you are the more force to need to get rolling but the more force you apply by standing on the pedal so it is somewhat self regulating.Anyhow.If we now add a mid drive motor to the crank we can see how significant the extra output is.Take the Shimano 6000 motor for example. This is quoted as having 70Nm of torque which is half what our rider is putting in, so in other words this motor would increase your pedaling output by an extra 50%.Hub motors have less torque but this is OK because they are not driving through the gear train. Consequently even a modest 25Nm hub motor will help significantly. This time we are adding the motor to the rear wheel where the rider's torque is 60Nm. So approximately a 40% increase in output.Of course the motors add weight to the bike and there's a battery to carry too, but anyone who has tried an E-bike will confirm that they put out more energy than they add in weight.But how much torque do we really need?Let's have a look at a fully loaded cargo bike and rider, this total mass could be 200Kg.And let's cycle up Bristol's famous Park Street. This is a 58m elevation change along a 300m distance; a tough ride even on a solo bike.

One of the clever things about a bicycle is that the heavier you are the more force to need to get rolling but the more force you apply by standing on the pedal so it is somewhat self regulating.Anyhow.If we now add a mid drive motor to the crank we can see how significant the extra output is.Take the Shimano 6000 motor for example. This is quoted as having 70Nm of torque which is half what our rider is putting in, so in other words this motor would increase your pedaling output by an extra 50%.Hub motors have less torque but this is OK because they are not driving through the gear train. Consequently even a modest 25Nm hub motor will help significantly. This time we are adding the motor to the rear wheel where the rider's torque is 60Nm. So approximately a 40% increase in output.Of course the motors add weight to the bike and there's a battery to carry too, but anyone who has tried an E-bike will confirm that they put out more energy than they add in weight.But how much torque do we really need?Let's have a look at a fully loaded cargo bike and rider, this total mass could be 200Kg.And let's cycle up Bristol's famous Park Street. This is a 58m elevation change along a 300m distance; a tough ride even on a solo bike. The first calculation is straight forward.We can work out the energy needed to lift the 200Kg's up 58 meters against gravity by using the potential Energy formula. This is because the potential energy stored by the loaded bike at the top of the street will be equal to the energy needed to get it to the top in the first place.Potential Energy = mghP.E = 200kg x 9.81 x 58m = 113.8KJHowever to work out the power we need to assign a time because power is "the rate" at which work is done.In scientific notation - The power P in watts (W) is equal to the energy E in joules (J), divided by the time period t. This makes sense as the shorter the time, the more energy is needed because we are moving faster.To keep things simple let's not try to move too fast; then we can ignore aerodynamic losses and if we assume a constant speed we can also use Newton's first law of motion to ignore acceleration changes.So let's set the climbing speed to a steady 8mph which is 12.8kph or 3.5m/s.Therefore the 300 meter stretch will take us 300m / 3.5m/s = 85 seconds (1.4minutes).Power = Energy / timePower = 113800j / 85s = 1338 watts or 1.338KwSo we will need 1.33kw to climb the hill from the bottom to the top.The torque is then the power divided by revs (in radians/second).A 26" wheeled bike will have a wheel circumference of about 2.34m.We are doing 3.5m/s so the wheel will turn ~1.5 turns each second which is 538° or ~ 9.38rads/sPutting that back into the power formula we get; 1338w = Torque x 9.38rads/sSo Torque required at the back wheel = 1338 / 9.38 = 142.64Nm.But as we know our rider will have to put more torque into the bike because the gearing favours a high-speed low torque output. So if we trace the torque back through the gear train with a 42t chain ring and 18t sprocket the torque required at the bottom bracker will be 142.62Nm x 42/18 = 332Nm of torque at the crank.A fully charged Shimano 6000 crank motor can put out 70Nm of torque so the rider will need to add 262Nm of torque to keep the bike climbing. This is equivalent to a 1497N push on the pedals but as we saw earlier an 80Kg rider only applies about half of this without heaving on the handlebars.This is where the mid drive motor displays an advantage. We can use a lower gear to reduce effort.So let's change down to a 36t sprocket at the back wheel.Now our 142Nm of torque at the wheel will only need 166Nm of torque at the crank.If motor adds 70Nm then the rider only has to add 96Nm or push on some 175mm cranks with 548N of force - which is possible. I reckon even I could manage that.So let's summarise this................The 70Nm mid-drive motor we have been looking at provides a very useful output particularly as it can benefit from the bike's gears to maximise its performance.The Park Street climb is an extreme example (especially at that speed with such a heavy bike), but it proves that moving cargo by bike, even in a hilly place, is easily possible thanks to the assistance provided by motors.Another interesting comparison might be made with the venerable Honda Cub 50.This durable little moped can move two people plus luggage besides, but how does its torque compare?

The first calculation is straight forward.We can work out the energy needed to lift the 200Kg's up 58 meters against gravity by using the potential Energy formula. This is because the potential energy stored by the loaded bike at the top of the street will be equal to the energy needed to get it to the top in the first place.Potential Energy = mghP.E = 200kg x 9.81 x 58m = 113.8KJHowever to work out the power we need to assign a time because power is "the rate" at which work is done.In scientific notation - The power P in watts (W) is equal to the energy E in joules (J), divided by the time period t. This makes sense as the shorter the time, the more energy is needed because we are moving faster.To keep things simple let's not try to move too fast; then we can ignore aerodynamic losses and if we assume a constant speed we can also use Newton's first law of motion to ignore acceleration changes.So let's set the climbing speed to a steady 8mph which is 12.8kph or 3.5m/s.Therefore the 300 meter stretch will take us 300m / 3.5m/s = 85 seconds (1.4minutes).Power = Energy / timePower = 113800j / 85s = 1338 watts or 1.338KwSo we will need 1.33kw to climb the hill from the bottom to the top.The torque is then the power divided by revs (in radians/second).A 26" wheeled bike will have a wheel circumference of about 2.34m.We are doing 3.5m/s so the wheel will turn ~1.5 turns each second which is 538° or ~ 9.38rads/sPutting that back into the power formula we get; 1338w = Torque x 9.38rads/sSo Torque required at the back wheel = 1338 / 9.38 = 142.64Nm.But as we know our rider will have to put more torque into the bike because the gearing favours a high-speed low torque output. So if we trace the torque back through the gear train with a 42t chain ring and 18t sprocket the torque required at the bottom bracker will be 142.62Nm x 42/18 = 332Nm of torque at the crank.A fully charged Shimano 6000 crank motor can put out 70Nm of torque so the rider will need to add 262Nm of torque to keep the bike climbing. This is equivalent to a 1497N push on the pedals but as we saw earlier an 80Kg rider only applies about half of this without heaving on the handlebars.This is where the mid drive motor displays an advantage. We can use a lower gear to reduce effort.So let's change down to a 36t sprocket at the back wheel.Now our 142Nm of torque at the wheel will only need 166Nm of torque at the crank.If motor adds 70Nm then the rider only has to add 96Nm or push on some 175mm cranks with 548N of force - which is possible. I reckon even I could manage that.So let's summarise this................The 70Nm mid-drive motor we have been looking at provides a very useful output particularly as it can benefit from the bike's gears to maximise its performance.The Park Street climb is an extreme example (especially at that speed with such a heavy bike), but it proves that moving cargo by bike, even in a hilly place, is easily possible thanks to the assistance provided by motors.Another interesting comparison might be made with the venerable Honda Cub 50.This durable little moped can move two people plus luggage besides, but how does its torque compare? The Honda torque output is a mere 3.6Nm at the engine crank but it uses reduction gears through its transmission.The primary drive increases this by x4.058 and then first gear gives a further increase of x3.272.Final drive ratio is typically 16/34.So this works out to 101Nm of torque at the rear wheel.But the Cub is heavier than a cargo bike. Add two people and it becomes heavier still and of course the cargo bike can capitalise on pedaled input as well. They are both great machines and go to show that you don't need masses of torque to create a useful vehicle.If you haven't tried an electric assisted box bke give us a call and take a test ride on us.

The Honda torque output is a mere 3.6Nm at the engine crank but it uses reduction gears through its transmission.The primary drive increases this by x4.058 and then first gear gives a further increase of x3.272.Final drive ratio is typically 16/34.So this works out to 101Nm of torque at the rear wheel.But the Cub is heavier than a cargo bike. Add two people and it becomes heavier still and of course the cargo bike can capitalise on pedaled input as well. They are both great machines and go to show that you don't need masses of torque to create a useful vehicle.If you haven't tried an electric assisted box bke give us a call and take a test ride on us.

We design and build bicycles in the South West of England, just outside Bristol.

Every bike is individual, each steel frame fashioned by hand, each weld unique and good function guaranteed

we are challenging the established notions of what’s possible by bike.

Nice people building good bikes.