Mention a tyre and most people will visualise a rubber band around a wheel to soften the ride and provide grip, but this seemingly simple device is actually quite complex. The complexity raises questions about which is the right tyre for a particular purpose and how you should choose a tyre for a particular vehicle.Without going into extreme depths, it is worth having a general look at some of the important characteristics of tyres and to observe a cross section of vehicles to understand which properties are most significant in a given situation.Let's look at efficiency, control, surfaces, pressures and tread.Efficiency.Efficiency of a wheel in motion, can be determined by a measure of its rolling resistance. The less resistance there is, the easier it will roll. This rolling resistance is dependent on many parameters including material of the tyre and the surface, soft or hard pavements, tyre widths and inflation pressures. However we can account for all these variables by measuring "rolling resistance".Some of the most efficient wheels can be seen on trains. These hard steel tyres form a very small contact patch on the smooth steel rail and this gives a very low rolling resistance.The downside of these steel wheels is that they cannot absorb bumps at all and this can generate a harsh ride and is the reason a super smooth surface (such as a rail) is provided. Their low friction also means wheel slip can occur easily under speed changes, and direction control is almost impossible without a flange on the wheel to guide against a rail.But the train wheel illustrates that for maximum efficiency we need low level of deformation of the tyre and surface. Control.Efficiency is important in cycling because of the modest power source, but it is not the only consideration.Any wheel driven road vehicle relies entirely on its tyres for vehicle control. Acceleration, braking and directional changes are all made relative to the road surface and the tyres provide the interface between the moving vehicle and the road. As discussed the steel wheel on a steel rail gives a high efficiency combination, but with limited control that would be unacceptable on any road going vehicle. Thankfully in 1888 Dunlop gave us the pneumatic tyre which, when fitted to any vehicle, provides unparalleled levels of comfort and grip. These days there are specialist tyres for every surface you might encounter from snow and ice, to gravel and mud, tarmacadam and velodrome. The reason motor sport is obsessed with tyres is because for any condition, maximising vehicle control can make the difference between winning and loosing and all of this control goes via the tyres to the road.Surfaces.To have any degree of control we need grip and this usually requires that one surface be compliant. Perhaps obvious, but a soft tyre on a hard surface would be better than two hard surfaces, although the latter is more efficient. Surface roughness also plays a part and this is why off road tyres have large open blocks of tread to grip against soft/unsurfaced roads. This is also why road surfaces are textured rather than totally glass smooth. Spiked tyres can be used on ice to create high levels of grip, in fact a rally car driven on ice with the correct tyres can create higher cornering forces than when driven on tarmac with slicks. An illustration that the right tyres for the right conditions makes a huge difference.PressuresTyre pressures present an interesting variable that can greatly change the capabilities of a tyre. Tyre life, grip, efficiency and control can be changed by varying tyre pressure. For example a tyre running on soft sand would benefit from a low pressure which would allow the tyre to "squash out" and create a larger footprint, less likely to sink in. However using this low pressure on the road at speed would be unnerving; the steering is likely to be vague and hitting any kind of obstacle could damage the wheel rim. Efficiency is also affected by tyre pressure. A higher pressure yields mush less rolling resistance and less energy expended in deforming the tyre. This is why racing bikes run with high tyre pressures. It is also true that high pressure tyres are less likely to puncture and less likely to wear prematurely.

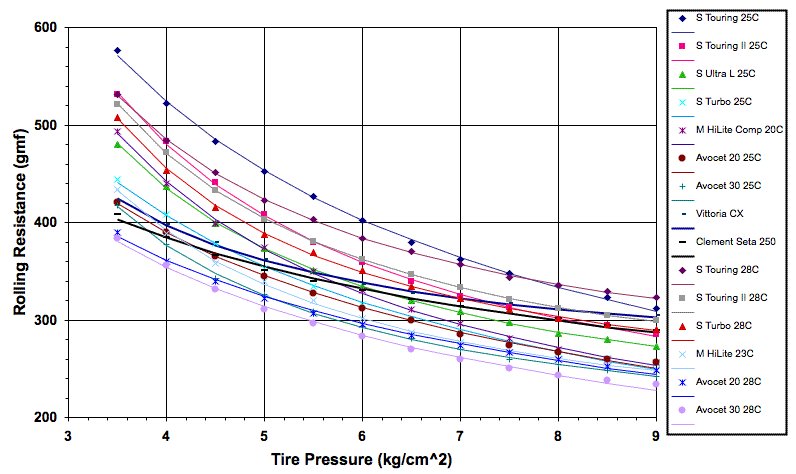

Control.Efficiency is important in cycling because of the modest power source, but it is not the only consideration.Any wheel driven road vehicle relies entirely on its tyres for vehicle control. Acceleration, braking and directional changes are all made relative to the road surface and the tyres provide the interface between the moving vehicle and the road. As discussed the steel wheel on a steel rail gives a high efficiency combination, but with limited control that would be unacceptable on any road going vehicle. Thankfully in 1888 Dunlop gave us the pneumatic tyre which, when fitted to any vehicle, provides unparalleled levels of comfort and grip. These days there are specialist tyres for every surface you might encounter from snow and ice, to gravel and mud, tarmacadam and velodrome. The reason motor sport is obsessed with tyres is because for any condition, maximising vehicle control can make the difference between winning and loosing and all of this control goes via the tyres to the road.Surfaces.To have any degree of control we need grip and this usually requires that one surface be compliant. Perhaps obvious, but a soft tyre on a hard surface would be better than two hard surfaces, although the latter is more efficient. Surface roughness also plays a part and this is why off road tyres have large open blocks of tread to grip against soft/unsurfaced roads. This is also why road surfaces are textured rather than totally glass smooth. Spiked tyres can be used on ice to create high levels of grip, in fact a rally car driven on ice with the correct tyres can create higher cornering forces than when driven on tarmac with slicks. An illustration that the right tyres for the right conditions makes a huge difference.PressuresTyre pressures present an interesting variable that can greatly change the capabilities of a tyre. Tyre life, grip, efficiency and control can be changed by varying tyre pressure. For example a tyre running on soft sand would benefit from a low pressure which would allow the tyre to "squash out" and create a larger footprint, less likely to sink in. However using this low pressure on the road at speed would be unnerving; the steering is likely to be vague and hitting any kind of obstacle could damage the wheel rim. Efficiency is also affected by tyre pressure. A higher pressure yields mush less rolling resistance and less energy expended in deforming the tyre. This is why racing bikes run with high tyre pressures. It is also true that high pressure tyres are less likely to puncture and less likely to wear prematurely. The graph clearly shows that whatever tyre you use, riding with a higher pressure reduces rolling resistance and therefore increases efficiency.However things change as the road surface degrades. On a bumpy road the more the tyre can absorb the bumps the more efficient the bicycle movement is. The reason is because less energy is used deflecting a soft tyre than is used to lift the whole bike over a bump which would happen with a high pressure tyre. Rider and bike weight also play a part in determining the correct tyre pressure.Tread.Some tyres are slick and others have very a aggressive tread pattern.Smooth/slick tyres give the maximum contact area for a given tyre width and therefore the maximum grip on a hard textured surface. Race bikes favour this sort of tread but it is less effective in rain or ice.Heavy treaded tyres for off-roading have blocks of rubber which can gain traction in soft ground and also self clear easily rather than clog up.For sand and snow there are super wide tyres running low pressures to give a large foot print to avoid sinking into the ground. These tyres also employ block treads for traction.

The graph clearly shows that whatever tyre you use, riding with a higher pressure reduces rolling resistance and therefore increases efficiency.However things change as the road surface degrades. On a bumpy road the more the tyre can absorb the bumps the more efficient the bicycle movement is. The reason is because less energy is used deflecting a soft tyre than is used to lift the whole bike over a bump which would happen with a high pressure tyre. Rider and bike weight also play a part in determining the correct tyre pressure.Tread.Some tyres are slick and others have very a aggressive tread pattern.Smooth/slick tyres give the maximum contact area for a given tyre width and therefore the maximum grip on a hard textured surface. Race bikes favour this sort of tread but it is less effective in rain or ice.Heavy treaded tyres for off-roading have blocks of rubber which can gain traction in soft ground and also self clear easily rather than clog up.For sand and snow there are super wide tyres running low pressures to give a large foot print to avoid sinking into the ground. These tyres also employ block treads for traction. More advanced tyres have a directional tread which is designed to be more effective but only in one direction. This is usually tailored towards wet weather riding where it is important to disperse water to avoid aquaplaning (skimming on top of puddles and loosing control).Motorcycles nearly always have directional tread, but interestingly the same tyre can be fitted differently, depending on which axle it is used on.Moped tyres are often the same front and back, but they are fitted to run in different directions. Notation on the tyre wall shows which way the tyre should be mounted depending which axle it is used on.

More advanced tyres have a directional tread which is designed to be more effective but only in one direction. This is usually tailored towards wet weather riding where it is important to disperse water to avoid aquaplaning (skimming on top of puddles and loosing control).Motorcycles nearly always have directional tread, but interestingly the same tyre can be fitted differently, depending on which axle it is used on.Moped tyres are often the same front and back, but they are fitted to run in different directions. Notation on the tyre wall shows which way the tyre should be mounted depending which axle it is used on. The reason for this is that the rear tyre is used for driving the bike forward and the front tyre principally for stopping. As the tyre works better in one direction running the tyre backwards on the front axle can give benefits.Bicycles.Let's apply this learning to bicycles.We know we will need an efficient tyre to get the most from our legs, but this should be considered a second requisite to the control needs which are vital to keep a rider safe. To keep it simple let's consider a cargo bike which will travel on surfaced roads. This will not need any aggressive "off-road" tread and in fact this could hurt the bike's efficiency, but some tread should be used for riding in wet and cold weather, over occasional mud and leaves.For our box bikes we generally recommend Schwalbe tyres which are durable and have good puncture resistance; something like a Marathon Plus should serve you well. Run them towards their maximum pressures for efficient running and to maximize life. This is typically about 40psi front and back but a little less if you ride solo and are light (60kg).

The reason for this is that the rear tyre is used for driving the bike forward and the front tyre principally for stopping. As the tyre works better in one direction running the tyre backwards on the front axle can give benefits.Bicycles.Let's apply this learning to bicycles.We know we will need an efficient tyre to get the most from our legs, but this should be considered a second requisite to the control needs which are vital to keep a rider safe. To keep it simple let's consider a cargo bike which will travel on surfaced roads. This will not need any aggressive "off-road" tread and in fact this could hurt the bike's efficiency, but some tread should be used for riding in wet and cold weather, over occasional mud and leaves.For our box bikes we generally recommend Schwalbe tyres which are durable and have good puncture resistance; something like a Marathon Plus should serve you well. Run them towards their maximum pressures for efficient running and to maximize life. This is typically about 40psi front and back but a little less if you ride solo and are light (60kg).

We design and build bicycles in the South West of England, just outside Bristol.

Every bike is individual, each steel frame fashioned by hand, each weld unique and good function guaranteed

we are challenging the established notions of what’s possible by bike.

Nice people building good bikes.